Reflections on Katrina: Supporting Others in Difficult Times

Degenkolb* staff was on-site to conduct an investigation on a homeowner’s claim. This time, the homeowner met the engineers and their Claims Coordinator at the site. Mounds of rubble lay in a heap on top of the slab where his house used to stand. As the engineers did their work, the homeowner sifted through what was left. Much of it was unrecognizable — items damaged during the storm had then sat outside, exposed to sun, humidity, and more rain for weeks and months. Many sentimental items were now beyond salvageable. The homeowner was looking for anything that had even remotely survived.

The home where the team had been that day was once used as a filming location for a major motion picture in the late ‘90s. At that time, the homeowner hadn’t accepted payment for the use of his home for filming. At the end of shooting, the crew presented him with a unique gift: A framed dollar bill signed by the crew and stars of the film, which included several major Hollywood actors. While sifting through the debris, he found the frame with the signed dollar bill intact. Excitedly, he showed it to Lisa, who shared in the man’s joy at finding at least one of his irreplaceable items. It was a small, but impactful, step forward in a long journey to recover and rebuild.

*Degenkolb Engineers acquired Barrish Pelham Consulting Engineers in 2018. Staff involved in the Hurricane Katrina recovery story were at the time employed by Barrish Pelham and are now employees of Degenkolb Engineers.

To learn more about Lisa’s journey and to help gain focus on investigative engineering for Ida, please reach out to lesquivel@degenkolb.com.

Want to submit a claim? Click here:

Facilitating the Design: A Case for Construction Engineering and Structural Engineering Co-Existing

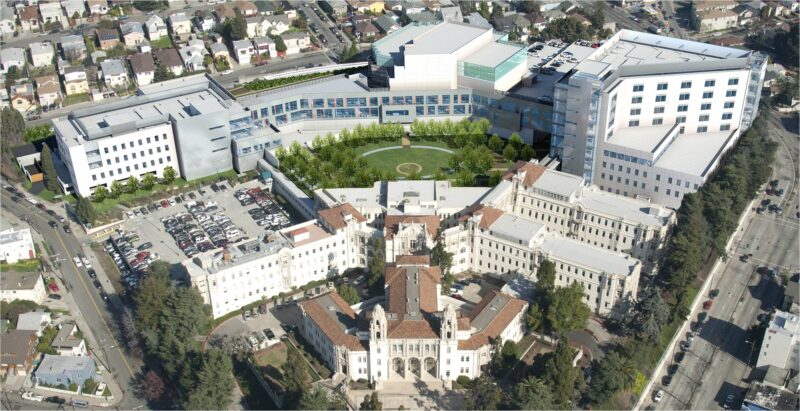

Before a critical building—like a healthcare facility—can open its doors to patients, medical personnel, researchers, and others, a design team is hard at work making sure the ideas can become a reality. A crucial step between design to opening day is construction engineering. Known at Degenkolb Engineers as CE for short, construction engineering facilitates the design of a structure by—sometimes literally—providing the necessary support which brings a design to life. Although CE serves to facilitate the design, its importance to the success of the whole project cannot be overstated. Robert Graff (Principal, San Francisco) knows this reality well. “Every project is different and shaped by the site itself.” Whether it’s accounting for existing adjacent structures, the unique geography of a lot, or every stakeholder involved, CE is there to find a solution.

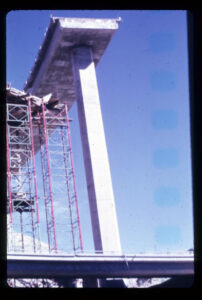

When building Highland Hospital’s new acute care tower in Oakland, CA, the design team encountered a challenge with the Satellite Building and a significant grade change from one end to the other. In addition, there was an existing building scheduled for demolition that partially retained this very grade change. Degenkolb was providing SEOR services for the new hospital tower as well as bridging documents for the Satellite building, but was also contracted to provide construction engineering services for the entire project. By engaging our CE team early, all involved were able to find an economical, efficient way forward. The solution: a three-story retaining wall—comprised of new shoring wall elements and existing building walls reinforced with new tie back anchors—that separates the Satellite building from the hillside. By employing this method, the building no longer had to serve as the retaining wall, which proved to be more cost-effective, improved the seismic performance of the building itself, and repurposed parts of the existing building to facilitate the new Satellite building. Additionally, this allowed the architects to have the building “be what it wanted to be,” preventing unnecessary architectural sacrifices that could affect the design’s vision.

From left to right: The original hill, the hill after excavation, and Andrew Scott (Principal, San Francisco) in front of the three-story retaining wall while it was under construction.

Highland Hospital also required the demolition of wing buildings to make the new acute care tower. The CE team planned for a selective demolition and shoring of part of the adjacent structures, which facilitated a more streamlined process before the foundations were laid. Thanks to these decisions during the excavation shoring, temporary building support, and historic building monitoring, the 315,000 square foot, nine-story, 169-bed acute care tower came to life with minimal delays.

Stories like these illustrate how costly design decisions requiring resources and effort can instead be spent in the CE world where creative solutions abound. In the case of Highland, the CE and structural design team were one of the same, run by separate project managers but under the same roof at Degenkolb Engineers. Often the design firm hires a subcontractor that then hires another subcontractor engineer to implement the shoring work, introducing them to the project far later in the design process. “The earlier CE can be in the room, the better,” Robert adds. Not only does earlier involvement prevent potential issues down the line—including making things more challenging and costly to build or even triggering a possible re-design—but can allow for ideas on alternative ways forward to bring stakeholders’ vision to life when creating the next world-class facility.

Robert adds that “the level of understanding, communication, and coordination by having it run out of the same office is happening organically rather than being forced.” This integrated approach has many benefits, especially when communication and coordination are key to CE’s success. Although the integrated CE approach is a rarity with facilities of Highland’s size, comparable projects focused on critical facilities can thrive along this path, making every stakeholder and member of the design team satisfied with the result they are delivering to the community.

How I Found Myself Upside Down in A Dumpster

A carrier adjuster contacted Degenkolb because they needed a forensic engineer to determine the cause of a failed fire sprinkler that had flooded an office area in a local commercial building. Just after 11:00 pm on the date of loss, the fire department received a notification that the sprinkler system for the building had been activated. After determining there was no fire, the fire department temporarily shut-off the fire sprinkler system. It was reported that a single fire sprinkler had failed and damaged the office area below it.

When I visited the site, I saw that all the cubicle furniture and carpet flooring had been removed from the roughly 50-foot by 50-foot square room. Additionally, the four acoustic tiles around the failed sprinkler were missing. The building manager told me that the four panels had been found on the ground the morning after the loss and were thrown in a dumpster at the back of the building.

I documented the existing conditions of the room and took a very close look at the failed sprinkler head. The mercury link for the fixture had been replaced and the fire protection system for the building had been reset and was properly functioning. I noted no evidence of distress on the surfaces of the fixture or long-term corrosion on the pipes and/or fittings. The pipe support hardware, the roof framing, and the surrounding building systems appeared intact and properly functioning. So, how did this single fire sprinkler in the middle of a conditioned office area fail? Where was my “smoking gun”?

I decided to check the dumpster at the back of the building. I needed to see the ceiling panels around the failed sprinkler head. I swallowed my pride, reflected on my desire to find the real cause of this loss, and did some dumpster diving, which is ultimately how I ended up upside down inside the dumpster. Thankfully, my efforts paid off! Under plastic sheeting and some carpet rolls, I found three of the four ceiling panels. They were tattered and damaged, but I was able to reassemble them on the ground next to the dumpster. Extending across two of the three panels, adjacent to the location of the fire sprinkler, were a series of black crescent-shaped shallow grooves in the acoustical panel surface. How and when did these Nike swoosh shaped markings get on the ceiling panels?

I returned inside where I met with the manager in his office and asked more questions about the building. Inside his office, the gadget-loving engineer in me immediately noticed a large remote-controlled helicopter sitting on the floor. The manager explained that several employees would fly the helicopter in the parking lot during lunch and, when not in use, it was normally stored in the damaged office area. The helicopter and its controls were found on the floor the morning after the sprinkler failed. I took a closer look at the helicopter and noted a white residue along the leading edges of the rotor blades.

Following this lead, I asked the manager if any employees were in the building when the fire sprinkler failed and he said no; he had been the last to leave the building earlier that evening. I then asked him if there is a cleaning service for the building and immediately his eyes popped wide open—something had clearly clicked for him. The manager accessed the security system for the building and found that around 10:30 pm on the date of loss, someone had accessed the building. The manager contacted the cleaning service company and they admitted that the employees in the office that night had been playing with the helicopter inside the office area when it flew out of their control, impacted the ceiling, and hit the fire sprinkler, which then triggered the fire suppression system.

This investigation shows that forensic engineering is about more than a single discipline; it’s about following clues, interpreting their meaning, and testing hypotheses. Whether the cause is obvious—like a tree has fallen through a roof or a car has gone through a wall—or harder to determine—like what’s causing mold growth inside a window—the first step in determining the cause is collecting evidence and making observations. With a little extra “diving” effort, asking pointed questions, and following the evidence, a forensic engineer can successfully determine the cause and origin of damage, even when it’s unexpected! This was one of those times.

Steve Moore, P.E., CASp

Read more of Steve’s articles here.

- The culprit was hiding in plain sight.

- After a quick dip into the dumpster, the pieces began to fall into place.

- Wetted acoustic tiles aren’t the most structurally stable.

When Swimming Pools Pop

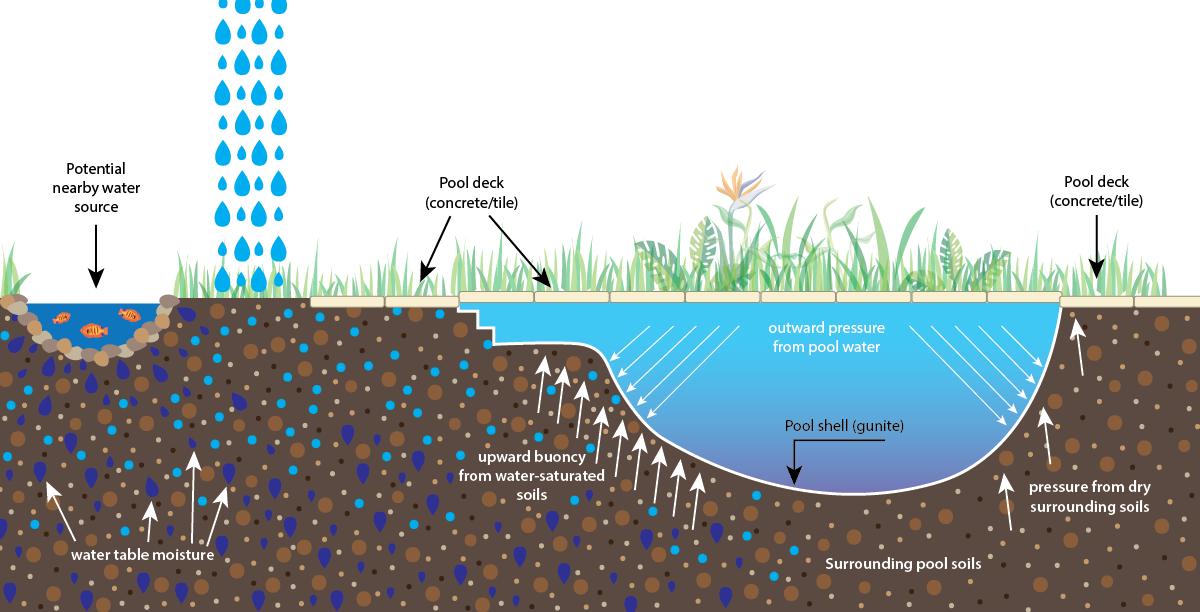

One type of property damage claim that Degenkolb’s Forensic Engineers see regarding residential pools is when the in-ground portion of the pool lifts–or pops up–out of the ground. Not only has the shell of the pool experienced irreparable damage, but the surrounding pool deck, the underground plumbing, and adjacent structures are also affected. But why does this happen?

In-ground pool shells are typically constructed of gunite, a material similar to concrete but applied via a spray gun directly onto the undisturbed soils of a pool excavation. Six inches of gunite creates the pool shell, and advantages to using it are its structural strength and variations in surface shape. Homeowners and designers can create whatever shape of pool they want, whether that’s a rectangle or more free-form curving shapes, like tunnels that lead into a home and swim up bars! Once the gunite dries and a plaster finish coat is applied, a shell is formed that holds the pool water.

The weight of the pool varies dramatically when empty or full, and this is where the real structural problems start to arise. In areas like California, the moisture content of the soils and the water table elevation vary from season to season, with more water in the ground during the winter months. If the local water table elevation rises to the depth of the pool due to a wet winter season, the buoyant force from displaced water tries to lift the shell up out of the ground. Fortunately, the weight of the gunite shell, the surrounding deck, and the water in the pool counteract these forces and keep the structure in the ground. But what happens when the water level of the pool rapidly drops or the water is removed from the pool for maintenance reasons?

Without the weight of the water in the pool, an elevated water table could produce large enough buoyant forces to lift the shell up out of the ground. Everyone has seen the extremely large cargo container ships and wondered how they stay afloat. Well, it’s all about Archimedes’ Principle, which states the buoyant force on a submerged object is equal to the weight of the volume of displaced water. Unfortunately, this is the moment when irreparable damage to the pool can occur. Not only are the plumbing pipes, electrical conduit, and surrounding deck damaged, but the soils under the gunite shell consolidate and fill the void—the shell cannot drop back down to its original elevation when the ground water table drops again.

So where would a pool owner or any interested party go to find out information about the ground water table in their neighborhood? Well, a couple of options would be to consult with a Contractor or Forensic Engineer specializing in swimming pool construction and installation. Another option would be to visit the California Department of Water Resources website and research historical data for wells.

If you are a pool owner and want to protect that fun and wonderful investment in your backyard try to keep an image in the back of your mind of ancient Archimedes lounging in his bathtub exclaiming that single word of discovery and enlightenment, “Eureka!”.

Read more of Steve Moore’s blog articles here.

Making the Case for Diversity, Equity, and Inclusion

Originally published in STRUCTURE Magazine in January 2021. Read the editorial on STRUCTURE Magazine’s site here.

Stacy Bartoletti, S.E., Chair CASE Executive Committee

Diversity, Equity, and Inclusion (DEI) have gained substantial exposure in 2020. Unfortunately, it has taken recent events of racism and abuse of power to bring it to the forefront. I hope the pain and loss associated with these events will not go to waste but will result in positive change. I do not consider myself an expert on DEI and even feel a bit exposed to critique by merely writing this editorial. Still, given my position in my firm and the profession, I feel it is my responsibility to talk about DEI and address it. I believe we all need to consider how we can positively impact DEI as individuals, as firm leaders within our firms, and through our professional organizations.

As an individual, I believe my first responsibility is to gain knowledge and understanding of DEI topics and issues. When I can, I read about the subject, participate in seminars and workshops, and engage in discussions with an open mind. I recently participated in a firm leader roundtable organized by the SE3 Committee of the Structural Engineers Association of Northern California and had two significant takeaways. First, I believe it matters how we talk about DEI, and the words we use are important. As preparation for the roundtable, we were all asked to watch a short video titled “Why I’m not a racist is only half of the story” by Robin DiAngelo. Robin talks about racism and how we as a society have defined the word brings up white defensiveness on the topic. I cannot do proper justice to the short video’s profound nature, so I recommend you search for it and watch it. My second takeaway is that we all have biases, and only by learning about them and exposing them can we address them. We need to bring our unconscious biases to the forefront when possible and make a conscious effort to mitigate their effects on our lives and businesses. This is not easy, but I can admit that I have biases, and I am actively trying to recognize them and address them.

As a firm and firm leader, I have an obligation to make sure that my business is creating a culture of Diversity, Equity, and Inclusion and taking active measures to address areas of deficiency. At my firm, we have recently established a DEI Council. The Council consists of a diverse group of employees that are committed to the mission of fostering an environment that attracts the best talent, values and recognizes diversity, and enables all employees to contribute and thrive while experiencing a culture of inclusion and belonging. The Council is tasked with bringing recommendations for change directly to the CEO and the leadership team. Our DEI Council is early in its work, and they are currently evaluating four specific areas.

Where and how we hire: The first step in this process is to address how we fill the candidate pool with diverse candidates and how we interview in a way that seeks to eliminate opportunities for bias to impact our decisions. To impact our candidate pool, we are re-thinking and expanding our search practices and are looking to identify events and job boards that serve underrepresented groups across many schools and regions. We also plan to review our interview practices across the firm to ensure that we have a consistent, structured interview process and a clear rubric with which to evaluate candidates. Providing structure in these areas and tools for our team to shine a light on areas that are prone to bias are essential steps toward meeting our DEI objectives.

Work opportunities: The Council works with those responsible for individual staff assignments to develop a tool to capture the needed experiences and desired experiences from all staff. The intent is to have a more formal procedure that will allow for bias in the process to be more easily identified and avoided. The process is also intended to create an equal playing field among those with different work styles, such as those that are more or less comfortable with being vocal about advocating for their own interests.

Inclusion: Starting with inclusion among departments and work styles, the Council is looking at who is invited to meetings and events, how are they held, which disciplines or personality types may not participate, and what we can do to help people feel that they belong. This work could also extend to firm practices regarding recognition, group meetings, and celebration of project success.

External partnerships and volunteering: The Council is identifying organizations that advance goals related to increasing the diversity of people getting into the engineering profession and considering ways to encourage and support our employees to participate with these organizations. The Council has identified the barriers to entry into the profession as an important focus area and will seek to partner with many of the excellent existing organizations to amplify their efforts.

At the Professional Organization level, I believe the most important thing we can do is speak with a common voice about DEI. Our professional organizations of CASE, NCSEA, and SEI can have a much more significant influence than any of us as individuals or firms, but it takes individuals with a passion to work on behalf of the organizations. In June of this year, the three organizations issued and signed a joint call to action to address DEI in our profession. There is an amazing amount of work underway to advance the Structural Engineering profession through these organizations, from education to licensure to leadership development and beyond. We can influence DEI in our profession if we infuse DEI principles and discussion into everyone one of those activities.

I encourage you to consider what you can do as an individual to expand your understanding of DEI, challenge your firms to be proactive, and engage with your professional organizations.

The Future of Science looks molecular at Stanford University’s ChEM-H / Neuro Research Complex

Sometimes building walls can break down others. This idea inspired the creation of Stanford University’s new state-of-the-art interdisciplinary research center known as the ChEM-H/Neuro Research Complex. Serving as the new home base for two existing institutes on the Palo Alto campus—Stanford ChEM-H (Chemistry, Engineering & Medicine for Human Health) and the Wu Tsai Neurosciences Institute—the complex unites the brightest minds in chemistry, engineering, biology, and medicine to collaborate in unlocking the mysteries of the human brain under the same roof.

The world-class 235,000 square foot complex addresses a variety of long-term challenges in human health across its 40 laboratories, shared research facilities, and meeting spaces. Stanford ChEM-H researchers focus on molecules in order understand life at a chemical level and improve the well-being of the individual and species. Findings reveal ways to cure and prevent disease as well as solve long-range issues that affect humankind. Recently, researchers discovered a never-before-seen biomolecule dubbed glycoRNA. This biomolecule could play a significant role in the biology of all living things and may even hold the key to possibly treating various autoimmune diseases.

The Wu Tsai Neurosciences Institute houses a range of disciplines, including cell and molecular biology, electrophysiology and behavior, imaging and microscopy, human neuroscience and engineering, and theoretical and computational neuroscience. Its researchers are dedicated to “understanding how the brain gives rise to mental life and behavior, both in health and in disease (source).” The Institute is at the forefront of neuroscientific exploration during a critical moment in the field as new technologies transform the way we study the brain, generating groundbreaking insights about the most complex organ of the human body. Several recent findings include uncovering how rebooting an immune cells’ metabolism can protect a mice’s aging brain, development of a new brain-computer interface with the fastest typing speed to date, and answers behind the mechanisms of autism.

Additionally, the complex features the Innovation Medicines Accelerator (IMA), a group which accelerates the translation of Stanford research discoveries into new medicines and strives to expand the wider community’s knowledge of human biology. The group seeks to overcome barriers to treatment for everything from cancer and the recent COVID-19 pandemic to rare disorders that are often less researched. The accelerator is one of four on the campus which aim to achieve Stanford’s Long-Range Vision. “Our Vision amplifies Stanford’s contributions through a new model for research universities: accelerating the creation and application of knowledge to tackle the world’s great problems, anchoring research and education in ethics and civic responsibility, and promoting access and inclusion (source).” The collaborative spaces in the new complex serve to amplify this purpose and the academic community’s impact on science, education, and knowledge.

Degenkolb’s Ariel Creagh, one of the complex’s design team members, poses in the courtyard at its Dedication Ceremony.

Degenkolb Engineers performed structural engineering services for Stanford University’s ChEM-H / Neuro Research Complex along with the design team: Ennead Architects LLP, Whiting-Turner Contracting Company, and others. In designing the innovative building, collaboration was at the forefront of the efforts by Degenkolb and the wider team to ensure a flowing, cohesive space without seismic joint or shear wall interruptions. Nearly a year later, the institute, thanks to its shedding of the traditional physical and figurative barriers in academic research, continues to push the limits of human discovery and the forge the future of science for the benefit of all.

When Mother Nature Forecloses on a Property

Several years ago, I investigated reported storm-related damages to a single-family residential structure near North Cove, Washington, between Tokeland and Grayland on the coast of the Pacific Ocean. It was reported that wind and erosion had caused near-complete destruction of the house. I was no stranger to storm-damaged structures, but I was not prepared for what I found.

I tried to drive to the location using my spiffy new GPS navigation system but kept encountering road closed and detour signs that appeared to be recently installed. I pulled over and got out to look. About 30 feet beyond a temporary folding traffic barricade sign, the asphalt pavement sheared off abruptly at the edge of the coastal bluff, about 20 feet above the beach below. I looked up and down the coast and saw numerous streets that terminated abruptly at the near vertical scarp of the coastal bluff. I could not help but picture the cover of Shel Silverstein’s classic collection, Where the Sidewalk Ends.

Risks of coastal erosion were well-known in the area, and other homes, businesses, and buildings had been lost in a similar way.

I returned to the car and, despite the lack of street signs and posted addresses, managed to find the house based on some old photographs and a rough description from the owner. I was astounded at what I found. The soils supporting the foundation of this house had washed out to sea and the west half of the house was resting on the beach, about 15 feet below the east half, which remained up on the bluff. The sandy soils of the bluffs were quite unstable, so I maintained a respectful distance as we documented the extent of the damages observed.

The area was a ghost town so there were no neighbors around to interview; I made a short drive up the coast to the Grayland Beach State Park, where Park Rangers at the park office informed me that particular section of beach had been nicknamed “Washaway Beach” and is one of the fastest-eroding coastlines in the world. It seems that every year the Pacific Ocean claims an average of 100 feet of coastline in this area as measured perpendicular to the shore. Thus far, the coastal erosion has claimed more than 50 houses, a lighthouse, a schoolhouse, and even a Coast Guard station.

The cause of the dramatic coastal erosion in North Cove is the erosion of the sand spit that once protected North Cove. Historic dredging and construction of hydroelectric dam projects on the Columbia River have altered the location of the drainage channel and created a condition in which southerly storm waves break close to the shore, greatly eroding the beach.

Left: North Cove, WA in June, 1990| Right: North Cove, WA in August, 2018 | Side by side images show the extent of erosion along that part of Washington’s coast.

Solutions considered to help protect the coastal communities in this region have trended away from the use of larger rip rap and other rigid armoring techniques in favor of an approach called “dynamic revetment,” in which a band of cobbles (3- to 10-inch diameter stones) is utilized at the base of the bluffs to absorb wave energy. The results of utilizing cobbles for dynamic revetment have been measurable and impressive, slowing erosion to rates as little as 30 feet per year in 2017 and zero in the 2018 – 2019 storm season.

While it was too late for the dwelling I was sent to investigate and for most of the property on which it was constructed, dynamic revetment is proving itself to be an effective mechanism for delaying the effects of coastal erosion in this region.

Written by Scott Thomas, April 23, 2021

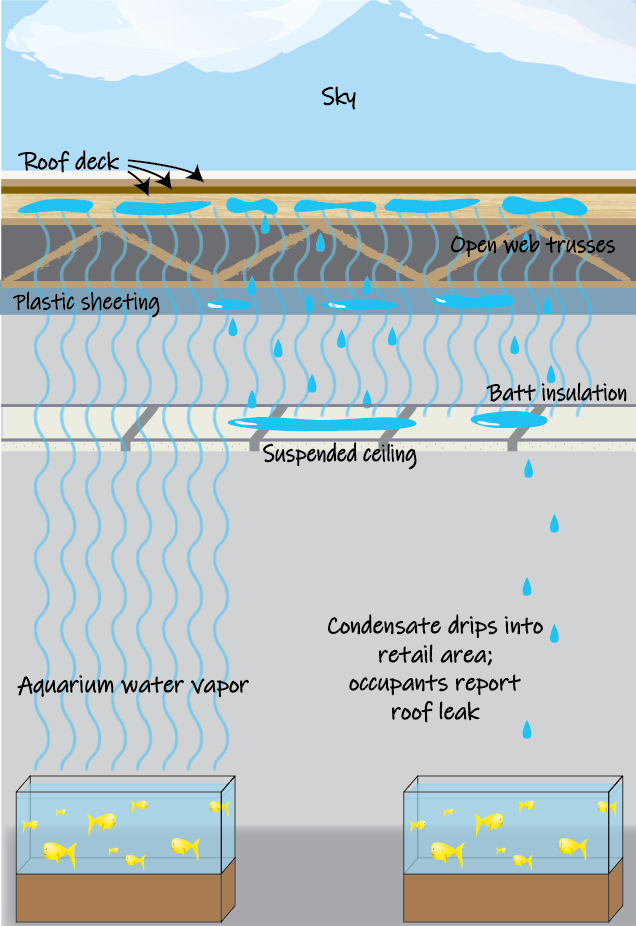

Water Falling on Fish

It was early Spring when I pulled up to a retail building where I’d been sent to investigate a collapsed roof. From the street, the only signs of something fishy was a slightly bowed parapet wall, which was leaning inwards. Once inside, the scope of damage was readily apparent—a large section of the central roof had completely collapsed. Amongst the wreckage of roof framing, ceiling panels, and wet insulation were damaged fish aquariums and their related accessories. The unmistakable scent of fish—earthy and musty, like fresh-tilled soil—lightly perfumed the air. Thankfully, most, if not all, of the aquariums’ finned inhabitants had been saved by the owners of this “fishstablishment.” But the pressing and immediate issue was the enormous hole in the roof—what had caused it?

As I combed through the debris, clues began to emerge. Ceiling tiles showed evidence of water staining; the metal ceiling grid was corroded with dark red rust, and the batt insulation was darkly stained and matted. Wood roof truss chords were darkly stained and covered with white and yellow mold. I took out my knife and inserted it into several of the mold-laden truss chords. Metal pins in the trusses were heavily corroded and the plywood roof sheathing was decayed and deteriorated. I also noticed a curious plastic sheeting, not dissimilar from radiant barrier material, had been stapled to the bottom truss chords.

I ventured into an area of the building where the roof had not collapsed and was able to observe the roof conditions. Even here, with some distance from the collapsed roof, there were signs of moisture exposure.

In search of additional clues, I ventured onto the roof. Like many commercial buildings, it was a shallow sloped roof with scuppers in the front parapet walls. Most of the roof appeared to be in good condition, with the exception of the collapsed area. Interestingly, I noted the collapsed had been patched over with additional roofing materials. Using Google Earth, I was able to determine that the patch had been recently installed—within the last several months—as it wasn’t present in the Google Earth image. The owner reported that during the last two years, multiple roof leaks had been repaired by a contractor. With my head swimming with information and seemingly related clues, i was primed to solve the puzzle, but I was floundering a bit for an answer.

The damage to the interior components was more severe and long-term than what one might expect from a roof collapse due to ponding. There also hadn’t been any significant rainstorms in the area for several weeks. As such, it was a seemingly a “blue sky collapse.” I reflect on the reported roof leaks and patching–perhaps a red herring? A hypothesis emerged—perhaps the roof wasn’t leaking from the outside; perhaps the water was coming from inside the building.

Among the roof debris and damaged aquariums stood a few that were spared; these aquariums had no covers, allowing water to easily evaporate from them. It all added up—numerous open aquariums had created warm, moist air conditions throughout the interior of the building. Water vapor migrated up through the ceiling, condensing on the underside of the cold roof deck. After wetting the wood, water droplets then fell back down onto the plastic sheeting and suspended ceiling surfaces. Not only were the aquariums producing water vapor, but as the daytime temperatures increased, the water trapped in the ceiling would again vaporize and rise up to the underside of the roof deck where it would later condense once again. There were multiple cycles of daily water vaporization and condensation occurring within the building, even during the spring and summer months!

The scale of the problem was large and permeated to all parts of the building. The worst of the damage, however, wasn’t readily visible to the occupants, as it was hidden behind layers of acoustic ceiling and plastic sheeting. This proved to be crucial in terms of insurance coverage and was an important aspect of our cause and origin report.

As I left the site, I didn’t want to waste what was left of a nice Spring day—carp-e diem! I thought, as I drove off into the sunset.

- Roof half wall leaning as a result of the collapsed roof.

- View of the collapsed part of the roof. Newer patch material readily visible.

- View of the collapsed roof from inside the building.

- Looking up to the sky through the hole in the roof.

- Deep blade embedment indicative of long-term moisture problems.

- Rusted and stained materials signaled long-term moisture issues.

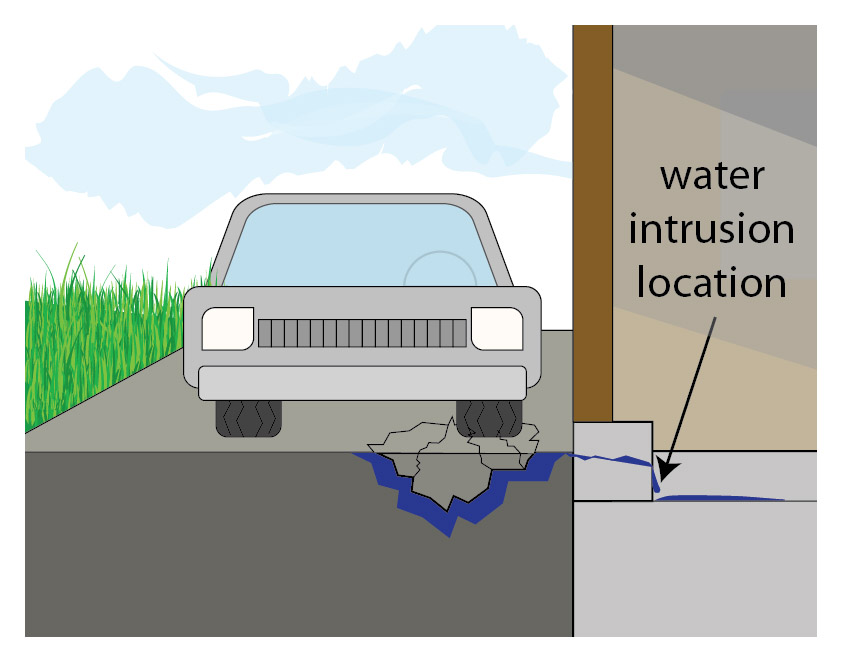

The Curious Case of the Pulsating Wall Leak

One of my more perplexing investigations was a case of reported water intrusion in a commercial fast-food restaurant. The water intrusion was reportedly occurring in the kitchen area, where limited food preparation and housekeeping activities occurred. The interior wall surfaces were finished with plastic laminate panels, which precluded direct examination of wall framing conditions.

Commercial food storage racks and tables further compounded access to an area where some interior finishes had been removed at the base of the wall, revealing a crack in the base of a concrete curb wall. Staining and wetted conditions were concentrated around the crack, so we cleared out the area and brought in some better lighting. Sure enough, the moisture-related damages and staining patterns were almost perfectly symmetrical around the crack in the concrete foundation curb.

And then we noticed something fascinating. The water wasn’t wicking into the building through the crack; it was pulsing into the building at a very low, but regular frequency. We noted that every 2 to 3 minutes, a small quantity of water flowed through the crack and into the building. This pattern was repeated over and over. Since there was no sewer or chemical odor associated with the liquid entering the building, I decided to have a look at the exterior face of the wall. I thought perhaps a malfunctioning sprinkler might be the cause.

Once outside, I had a look at the exterior face of the foundation. There were no planter strips or malfunctioning sprinklers. The concrete paved drive lane was immediately adjacent to the wall and cracked curb. Puzzled, I sat there a bit and watched the cars lining up for their lattes and frappes. I marveled at how quickly the restaurant was able to get the customers through the lines…almost every 2 to 3 minutes!

This was my aha moment.

During a rare lull in the flow of traffic through the pickup window, I had a close look at the concrete pavement. It was in rough shape, and the slab had been fractured into several subsections with multiple through-depth cracks. While examining the slab, a VW Passat interrupted my musing. As I watched the relatively lightweight passenger vehicle drive over the cracked pavement, I noted the behavior of one particularly mischievous section. It appeared to rock back and forth approximately ½ inch under the weight of each passing wheel load. The standing puddle next to the slab section, an unwitting co-conspirator, would temporarily empty before being refilled by the adjacent saturated soils.

What I realized is that the cars – by simply driving over the broken concrete slab section – were unwittingly pumping water into the building.

This one was an easy fix – a properly reinforced replacement drive slab – and problem solved. But diagnosing it required good observation skills and the ability to make connections—the cadence of the water intrusion matching that of the cars going through the line tipped me off to the source of the problem. I decided to treat myself to a celebratory beverage.

Make that a tall Americano, please, straight up – no extra pumps.

Always Pet the Dog

It was a grey, rainy day in the Pacific Northwest. I was investigating reported roof leaks at a single-family residence on behalf of a major homeowner’s insurance provider. The insured/owner of the house was a 75-year-old widowed man who lived alone except for his dog, a Labrador retriever. The house was cold, dimly lit, and smelled faintly of mildew. A quick glance around the interior revealed aged interior finish stains that spoke of a history of moisture contact.

The owner was suspicious and nearly directly accused me of being a “hired gun” for the insurance company. He was certain that I was there to deny his claim and any sort of money he might have coming to him. I tried to explain that I was an engineer hired by his insurance company to investigate the damage and provide my opinion on the cause(s) of the damage that had been reported, but my explanation fell on deaf ears. My questions about the history of the roofing materials and interior paint recoatings were met with gruff, nonresponsive answers. He scowled as he looked over my business card and bag of tools and test instruments, then muttered something about getting it over with.

As I examined the attic space, the tidal-pattern stains on the sheathing and the absence of ventilation gave classic indications of an aged and ongoing problem. The attic examination also revealed the presence of wood rot at the sheathing and framing members, making it unsafe to directly access the roof. I then moved my examination outside. From the safety of a ladder, I was able to access the roof and observe the three-tab asphalt shingles, numerous missing shingles, exposed and faded roofing underlayment, and a patchwork of temporary shingle repairs that had become permanent over time.

I returned my attention to the homeowner to discuss my observations and ask some follow up questions regarding the shingles and history of repairs. The homeowner was still suspicious, and even cagey with his responses. I spotted the dog over on his bed in the corner of the room; to satisfy his apparent curiosity about this visitor in his house, I walked over, knelt down, and began to pet the dog. I was immediately met with a welcoming dog smile and a thumping tail. I asked the homeowner how old his dog was and his name.

“Buck’s fourteen; all I got left now,” said the homeowner, still a bit gruff.

I continued to scratch Buck’s ears, clearly earning the approval of the dog.

“I put that roof on myself. Must’ve been….30? Maybe 35 years ago,” the homeowner shared, unprompted. He seemed to be softening his stance a bit. I complimented his effort and told him that I had shingled my roof in 2005 with my brother-in-law. He nodded, knowingly.

I shared that it was the hardest work I’ve ever done – that there’s a reason there aren’t any old roofers. That comment got a smile out of him.

“Yeah, that old roof got us through some tough times. Seen some storms. Patched it up a few times.” He paused a bit, then went on. “At first it was just a few stains, but it’s gotten a lot worse over time. What do you think; will I get any money? I’m on a fixed income, you know…”

I reminded him that I wasn’t an adjuster and that those decisions weren’t mine to make. He looked satisfied with my explanation but had questions about the next steps in the process. I explained that I would report to his adjuster what I had seen and discussed with him, and that they would likely want a written report, which would take a bit of time to produce.

The dog was now on its back, letting me know the ideal spot to scratch for maximum dog relaxation. The owner, too, seemed a lot more relaxed than when I’d arrived at his doorstep.

“Do you think it’s time for a new roof? I don’t know how I’m going to afford it…” he lamented.

I replied that I understood, but I felt that 25 years is about the end of the useful service life of a 3-tab asphalt shingle roof. I joked with him that if he got 30 or 35 years out of his, he was ahead of the game. We laughed together as I picked up my tools and headed for the door. I shook his hand and thanked him for his time. He smiled and thanked me for mine and for the information about his house. As I opened the door to leave, a cold wet nose pressed up against my hand for one last scratch.

* * *

Always pet the dog is advice I give to all investigators. It’s a metaphor for extending empathy in our technical investigations and for never losing sight of the people – and dogs – with whom we come in contact. It can go a long way in establishing trust and understanding and facilitating communication in arenas where adversarial positions are far too common.

The Nisqually Earthquake 20 Years Later

On the morning of February 28, 2001, moments before 10:54 a.m., Lisette Terry (Degenkolb Associate) had just stepped out of the shower in her apartment before class at the University of Washington. “I noticed my kitchen ceiling was bouncing, and shortly after I felt the floor start moving like the entire building was waving on fluid. The way the structure swayed—it felt like I was riding a surfboard.”

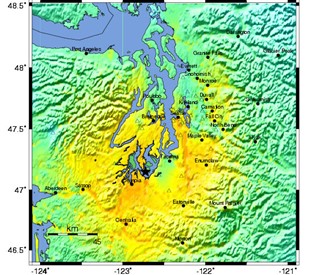

What she was experiencing would come to be known as the Nisqually earthquake, a 6.8 moment magnitude event that began 35 miles underneath southern Puget Sound as the Juan de Fuca Plate sank further into the Earth’s mantle. The quake’s epicenter was northeast of Olympia, Washington, near the Nisqually Delta—its namesake—and was felt as far north as Vancouver, B.C. and east as Salt Lake City. In a matter of 40 seconds, the quake injured hundreds of people, killed one, and caused an estimated $2 billion in property damage.

The star marks the epicenter of the Nisqually earthquake in February 2001.

Nisqually’s Impact on Degenkolb

Nisqually may have lasted for less than a minute, but its effects forever altered Washington State’s seismic response and Degenkolb’s trajectory in the Pacific Northwest region. “Nisqually was the impetus behind the founding of Degenkolb’s Seattle office,” recalls Stacy Bartoletti (Degenkolb CEO). He remembered feeling the quake’s shaking from 145 miles away in Portland at Degenkolb’s 12th-floor office that February morning 20 years ago. Stacy connected shortly after with Travelers due to the firm’s prior collaboration with the insurance company following the 1994 Northridge quake. Throughout that year, he and other Degenkolb project managers began traveling back and forth to Seattle, working on a range of projects with Travelers, including assessing post-earthquake damage to clients’ buildings and other related claims work. Some of this work featured the hard-hit Old Town—also known as Pioneer Square—in downtown Seattle with its historic unreinforced masonry (URM) buildings that bore the brunt of the temblor’s damage.

“There was a lot of professional activity work after the quake centered around looking at various scenarios and expanding seismic awareness on a state-wide level,” recalls Stacy. Degenkolb has been involved since the inception of these efforts, helping guide the state and community to become more resilient for the next quake. Cale Ash (Degenkolb Principal) joined the Degenkolb Seattle office in 2003 as its first Designer. He quickly became involved in the ongoing seismic efforts and projects of the firm, including the Cascadia Region Earthquake Workgroup (CREW) and the Earthquake Engineering Research Institute’s (EERI) Seattle Fault Scenario: a document that “communicates the impact of a quake to a wider audience so it can be used for future preparation,” he describes. “I saw that as a valuable way to get further involved in earthquake risk-reduction activities.” Many others in the Seattle office and beyond have since followed suit, including Kyle Steuck (Degenkolb Associate Principal) whose interest in seismic hazard and loss analysis led to his involvement with EERI. He has gone on to serve as the President of the Washington State chapter.

The current Seattle Office lobby.

Seismic Resilience in Washington State

Nearly a decade after Nisqually, the state rejuvenated the Washington Seismic Safety Committee (WSSC). As part of the WSSC, Degenkolb played a significant role in developing Resilient Washington State—a policy and planning document published in November 2012 by a subcommittee that Stacy chaired. Resilient Washington State strived to quantify the state’s seismic risk and the impact on its systems if another damaging earthquake occurred. This marked the beginning of a line of work meant to facilitate state-level implementation of seismic risk reduction over a 50-year period. With eight years under its belt, Stacy notes that “there is work being done but the Initiative is relatively in its infancy.”

Part of that continuing work towards seismic risk reduction includes seismic upgrades. “The Nisqually quake made many recognize the hazard and take action,” notes Stacy. Two decades later, URM structures—like those damaged in Seattle’s Pioneer Square—remain standing with many still awaiting retrofits. Despite the known risk of URM structures, Stacy notes that it has taken decades to deal with URM buildings due to the required “wherewithal” among stakeholders to make it possible and the sheer number of outstanding structures. Cale adds: “Earthquake risk reduction is not solely an engineering endeavor. It needs to involve community to be effective.” He cites the technical requirements of the proposed City of Seattle’s URM Ordinance and how officials had trouble gaining public support for more than 10 years around retrofit mandates before it was passed. “We have helped our clients understand these requirements—that they are likely to come into play at some point—and we’ve advised them as they consider proactively retrofitting their buildings,” he adds.

Some of these outstanding URM buildings happen to be schools which originally opened before this construction type was phased out in the mid-1950s and which pose a risk for Washingtonian students. Degenkolb’s involvement with the Washington State School Seismic Retrofit Pilot Project through the WSSC sought to find methods for assessing the earthquake performance of schools and offer recommendations for future actions. Lisette (Degenkolb Associate) knows the risk all too well. Her daughter currently attends one of the older URM schools that is slated to be seismically retrofitted in 2024. “Her school is more than 100 years old. I read a structural engineer’s assessment of the building before she went to kindergarten there and the findings were not good.” Cale recognizes that Nisqually launched an unprecedented amount of seismic work but knows that there is still much work to be done for seismic safety of schools and other URM structures statewide. The advocacy and research efforts that Degenkolb has participated in through the WSSC and beyond have helped galvanize support and promote understanding of Washington’s seismic risk.

Example of a URM building damaged by Nisqually.

Seattle’s Seismic Risk

Beyond schools, the seismic resilience of hospitals and other healthcare facilities remains a significant concern. Mike Bramhall (Degenkolb Principal) recalls being summoned to Harborview Medical Center— the designated disaster control hospital for Seattle and King County—a few hours after Nisqually hit. He was one of the few engineers available to travel to the hospital to conduct a rapid assessment of any damage. In the seven hours he spent on site, Mike “can distinctly remember a seismic joint on the fourth floor [of one of the buildings]. The building moved enough that it damaged the cover, so you could look inside the joint and see the blue sky through it.” Despite the structural damage, he was able to give the hospital the go-ahead to remain in operation—welcome news to the many of injured from Nisqually who were transported there for treatment.

Mike reflects on his concerns around the effect a larger quake may have not only on Seattle’s medical response to a disaster but the bustling city’s infrastructure. “Seattle is unique in that it’s very linear. The north part of Seattle is cut off from downtown and the south side by lakes and bridges. If one of the bridges goes down, you must drive around 80 miles to get from one side of the city to another. If a quake damages the I-5 Ship Canal Bridge you almost effectively cut off all traffic of goods and services going north. Other cities have that but not to the degree that Seattle does.” In other words, seismic resilience translates to economic resilience. Lisette reflects on the now defunct Alaskan Way Viaduct, a roadway that eventually was torn down due to deficiencies illuminated by Nisqually and a notorious predecessor— the Loma Prieta earthquake. “I thought about seismic risk a lot when I used to drive on the viaduct [before it was demolished]. I had a fear of being pancaked,” says Lisette.

Downtown Seattle looking towards Mt. Rainier.

Looking Forward

“Nisqually was an eye-opening time for the region and for Washington State to do more to mitigate the earthquake hazard,” notes Stacy. David Sommer (Degenkolb Associate) reflects on Nisqually’s legacy and how much of the work and effort being performed is geared toward another looming threat: The Big One. “People around here don’t realize that Nisqually was not a large quake, so trying to educate our clients about what the Cascadia Subduction Zone could do to the area can be a struggle. People remember some chimneys falling after Nisqually and believe that ‘we’re going to be okay.’ However, the Cascadia Subduction Zone and Seattle Fault scenarios could literally change the landscape of Seattle.”

Many in the earthquake community face the same challenge. “While Nisqually is a good reminder that we are in a seismically active area, there are bigger earthquakes we need to keep in mind and address,” cautions Cale. “Nisqually is the type of earthquake we can expect to see every 30 to 50 years whereas larger events that we are trying to prepare for are what we expect to see every 300 to 500 years. It’s now been roughly 320 years since the last Cascadia Subduction Zone event, so we’re in the potential ‘sweet spot’ geologically.” Stacy adds: “Seismicity and seismic risk are well known in the Pacific Northwest now. There is a tremendous amount of work that needs to continue to happen or ramp up.” Degenkolb remains active in building seismic resiliency alongside our peers thanks to the heightened awareness generated by Nisqually two decades ago.

Sylmar Earthquake Legacy – Part III

The 1971 Sylmar earthquake put a new spotlight on the need for healthcare buildings to withstand seismic forces. The Veterans Administration Hospital complex located in Sylmar suffered severe damage; four buildings collapsed and there was a significant loss of life. In response, the VA began working on its own stringent design standards for its buildings and healthcare facilities. According to Chris Poland, emeritus CEO (1990 – 2013), the VA really blazed the trail when it came to hospital design. For non-VA facilities, however, it was the Alquist-Priolo Act, which was modeled after The Field Act, that made it the state’s responsibility to review the plans for public facilities, including hospitals and schools. The Act also facilitated the process of retrofitting existing buildings. Henry was one of the authors of this watershed piece of legislation. However, the reviewing body, an early version of OSHPD, didn’t have the expertise to evaluate the structural aspect of essential facilities nor did the Office of the State Architect (OSA, now the Department of the State Architect). To remedy this, they contracted with structural experts, including Degenkolb Engineers, to provide reviews (OSHPD eventually built up its structural expertise).

With the Alquist-Priolo Act enacted into law, buildings needed to be constructed to a higher standard, but the building codes hadn’t yet caught up to these new mandates. So in the early ‘70s, following the Sylmar earthquake, Degenkolb found itself in an interesting position; in collaboration with the OSA and OSHPD, they and other leading seismic engineers were developing best practices and mapping out guidelines as they went along. Simultaneously, Degenkolb was also working with the VA on their new hospitals, including one at Loma Linda, which were being constructed under different, but equally (or possibly more), stringent seismic design requirements.

Healthcare design review through OSHPD has changed significantly since then; the organization has worked to build up its structural expertise (though it still collaborates with experts in the field), review processes have adapted to be more streamlined and provide feedback on a faster cycle, and new technologies have been integrated. Outside OSHPD, the building codes have been updated to reflect better building practices based on a real-life understanding of how buildings perform as well as rigorous academic seismic research. And though there is not yet a way to predict when an earthquake will strike, legislation like the Alquist-Priolo Act preempt building safety by weaving seismic performance considerations into law.

Some hospitals, however, are looking beyond what’s required now and planning and building for the needs of the future. According to Jorn Halle, Practice Area Leader for Degenkolb’s healthcare group, “The healthcare field is ripe for innovation.” In fact, he says, some healthcare groups are already thinking of ways to future-proof their facilities. A hospital built today may be expected to last for 60, 80, 100 years. “What are things going to be like in 2100?” asks Jorn.

Current events give a taste of what might be to come, such as creating flexible spaces that can be quickly adapted to provide acute care during pandemics and designing ventilation systems that can prevent the spread of viruses as well as operate efficiently during major fires (when exterior air quality is hazardous). As technology and artificial intelligence advances, how will that affect the design of buildings? For example, will the vibration control criteria of surgical floors become more stringent as robot-assisted surgery becomes more common-place? Planning for these things now—or at least designing for the possibility of facility adaptability and change—goes beyond what’s currently required in the code. But when designing a hospital that may still be in operation a century from now, this is the kind of future planning that puts Degenkolb at the cutting edge of healthcare facility design.

Sylmar Earthquake Legacy – Part II

Continued from Part I of our Sylmar Earthquake Series

Before the Sylmar earthquake, the only major piece of legislation to mandate earthquake-resistant construction was The Field Act, which was passed after the 1933 Long Beach earthquake and authored, in part, by John Gould, a Degenkolb Founder. The Field Act only targeted California schools, but it marked the start of government-mandated regulations for how to build in earthquake country. Henry Degenkolb’s contribution to earthquake engineering included his work conducting materials and connection testing work at Treasure Island, authoring numerous technical publications, and visiting the sites of major earthquakes around the world to observe, photograph, and document conditions, deepening his understanding of how buildings performed during major seismic events. By 1971, Henry was regarded as a leading earthquake engineer, and Degenkolb Engineers was a well-known seismic firm.

Based on the damage and seismograph readings from Sylmar, it became apparent that earthquakes performed much differently than had previously been understood, particularly when it came to strong ground motion. During the ‘quake, the shaking was stronger, it lasted longer, and it underwent pulses. Suddenly, the profession realized it had to start thinking about building design differently and taking steps to understand them more thoroughly. The Sylmar earthquake drew attention to the need for even more seismic instruments in buildings and on the ground to record seismic events when they happened. Chris Poland, CEO emeritus of Degenkolb (1990 to 2013) led the committee that was part of the California Strong Motion Instrumentation Program (CSMIP), which placed seismographs throughout California.

Amongst the rubble of damaged buildings, one common failure point started to emerge: non-ductile concrete. Though still a kid in ’71, Jay Love, Degenkolb Senior Principal says that the Sylmar earthquake had a significant effect on the industry’s understanding of non-ductile concrete and the importance of horizontal ties in the rebar detailing of concrete columns. Jay points to Olive View Hospital, where much of the aesthetic of the building’s design included exposed concrete and concrete columns. Concrete, though strong, isn’t flexible on its own. Unlike steel, which can bend and flex without breaking, unreinforced or poorly reinforced concrete cannot; when it fails, it bursts apart. In 1971, rebar was being used to reinforce concrete columns, though most of the rebar was installed vertically. This configuration provided support and strength to the concrete column for gravity loads, but it couldn’t prevent the brittle shear failures.

During the Sylmar earthquake, the concrete columns experienced lateral forces—they shook side to side. The lack of horizontal ties allowed shear failures to occur. Additionally, because the vertical rebar lacked sufficient horizontal ties, these vertical bars buckled and the concrete material shattered, which often caused the entire column to collapse. Though it wasn’t the first time the industry had seen non-ductile concrete failures during an earthquake, the extent of it and the resulting damage in 1971 was alarming. Based on lessons learned from Sylmar and other earthquakes, as well as seismic research conducted at leading research institutes throughout the world, ductile concrete is now standard in the industry.

Sylmar Earthquake Legacy – Part I

At 6:00 in the morning on February 9, 1971, an earthquake occurred in the foothills of the San Gabriel Mountains of Southern California, affecting areas around the greater Los Angeles area, particularly Sylmar and the San Fernando Valley. Lasting about a minute, with 12 seconds of strong ground motion detected by seismograms. It was the first major earthquake to hit the region since the 1933 Long Beach Earthquake, and was the most documented event at that time thanks to a dense network of 241 seismometers. One seismometer installed at the Pacoima Dam recorded a peak horizontal acceleration of 1.25 g, which was more than twice what had ever been seen during an earthquake before.

Olive View Hospital sustained significant damage following the Sylmar Earthquake on the morning of Feb. 9, 1971.

When it hit, the newly constructed Olive View Hospital, which had only been opened 6 weeks earlier, sustained significant damage; four buildings at the Veterans Association Hospital complex completely collapsed, causing significant loss of life. The upper and lower Van Norman Dams were severely damaged, and 80,000 people were evacuated because the lower dam was close to breaching. Highways and freeways throughout the area were affected when sections of bridges and exit ramps collapsed. School buildings were also damaged, but the ones that had been constructed or reinforced after the Field Act went into effect (following the 1933 Long Beach Earthquake) fared far better than those that hadn’t.

In 1971, Degenkolb was a 20-person firm. Located in San Francisco, over 300 miles north, no one working at Degenkolb at the time felt the ‘quake, but they certainly heard about it. Henry Degenkolb was invited almost immediately to visit the Olive View Hospital, but he was unable to go at that time, so Loring Wyllie went instead. His first trip primarily focused on the hospital, but he returned on subsequent trips, visiting numerous Woolworth’s department stores throughout the LA area, as well as a water filtration plant on the shores of upper Van Norman Lake.

It is the water filtration plant that really stands out in Loring’s memory, however. While visiting the Jensen Water Filtration Plant, Loring was asked to inspect a damaged water reservoir. Constructed essentially as a rectangle, with the sides below-grade and top level (or ceiling) level with the ground, the facility had sustained heavy damage. During construction, the contractor had piled up to 6 feet of dirt on top of the concrete ceiling to prevent buoyancy (when empty, these types of structures tend to “pop” out of the ground due to lateral and upward forces). After the earthquake, they set up scaffolding inside the reservoir to see what condition it was in. As one of the engineers there to see the facility and document the damage, Loring climbed up the scaffolding to the roof of the reservoir. As he stood on wiggly scaffolding, in the dark, with broken rebar sticking out at odd angles, thousands of pounds of damaged concrete and loose dirt above his head, his knees started shaking when he made an alarming but intriguing observation: the 500-foot-long concrete slab roof had slid back and forth in excess of 2 feet during the earthquake along a construction joint. After making his observation and documenting the conditions, Loring was happy to climb safely out of the water reservoir.

- Degenkolb engineer Loring Wyllie visited the Jensen Water Filtration Plant after the earthquake.

- He went inside a large water reservoir to assess damage.

- The 500-foot-long concrete ceiling had moved significantly.

- Today, the water reservoir is still in use after having been fixed.

The Sylmar Earthquake upended the general understanding of how powerful an earthquake could be. In the case of schools, it also provided an opportunity to observe the positive results of the Field Act; schools that had been reinforced under the Field Act (authored, in part, by Degenkolb Founder John Gould) performed better than unreinforced buildings. As a result of the Sylmar earthquake, significant changes were made to the building codes and to how healthcare facilities were built, ultimately setting off the formation of OSHPD. Read more about this in Part 2 of our series on the Sylmar earthquake.

- The Sylmar Earthquake hit on Feb. 9, 1971 at 6:00 a.m.

- Transportation infrastructure was significantly damaged around the Los Angeles area.

- Bridges and highway exits collapsed during the earthquake.

- Olive View Hospital sustained significant damage following the Sylmar Earthquake on the morning of Feb. 9, 1971.

- The hospital had only been open 6 weeks at the time of the earthquake.

- Degenkolb representatives traveled to Olive View Hospital to assess the damage.

- Non-ductile concrete, in particular, performed poorly during the earthquake.

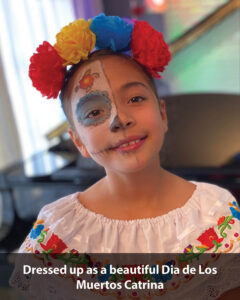

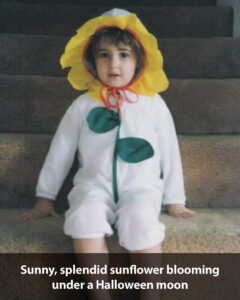

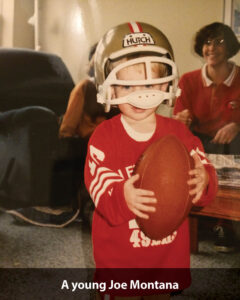

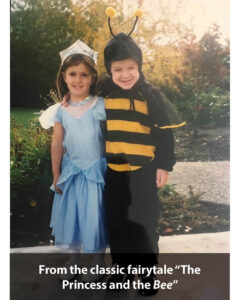

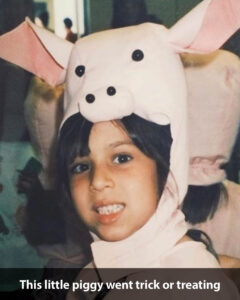

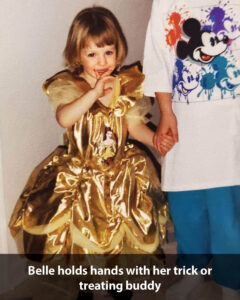

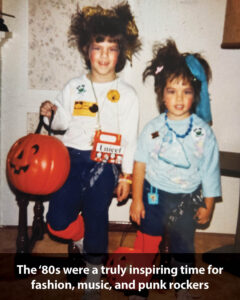

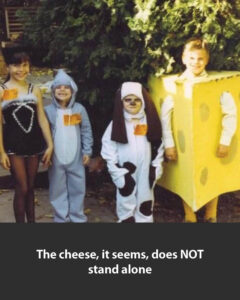

Happy Halloween!

Check out these cute pictures of Degenkolbers as kids, or their own kids, from Halloweens past