Structural Engineering Solutions for Science & Technology

By partnering with owners and AEC firms, we provide innovative solutions that accelerate project timelines, minimize disruptions, and align with long-term business goals. Our expertise spans technology workplaces, life sciences, clean energy, data centers, and manufacturing facilities.

Clients seeking rapid decision-making, deep expertise in existing-building projects, and integration of seismic risk mitigation strategies turn to us for support. They rely on our advanced technologies and long-standing understanding of industry norms and best practices to deliver proactive, customized solutions.

As demand grows for technologically enhanced office spaces, manufacturing expansion, and sustainable infrastructure, we remain committed to delivering high-quality structural engineering services. Whether navigating seismic requirements, modernizing lab spaces, or supporting clean energy initiatives, we are a trusted partner in shaping the future of science and technology facilities.

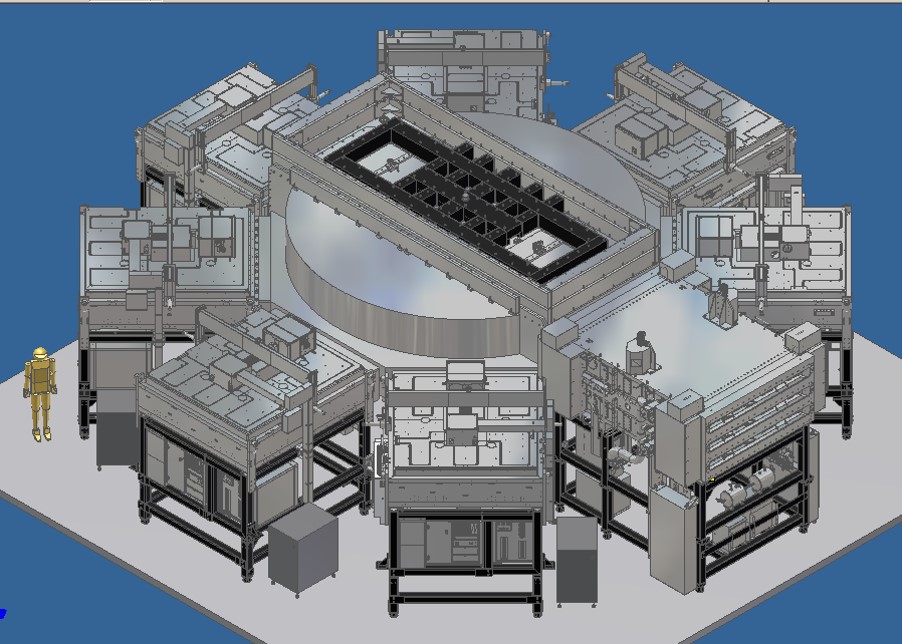

Clean Energy & Utilities

Supporting the transition to sustainable energy with engineering for battery storage, hydrogen, and utility infrastructure.

Keeping Your Business in Operation

While many structural engineers can retrofit buildings, we provide a complete risk management solution. We can analyze your entire portfolio; identify your risk; ask the questions that bring you the right solution for your specific needs; provide post-earthquake training and pre-purchase and pre-lease investigations; evaluate and retrofit buildings according to your preferred performance level; and provide standards for future purchases or leases. We work beside our clients to understand their business and the impact each facility has on their operations and bottom line.

Data Centers

Engineering support for new and existing data centers to meet the growing demand for AI and cloud computing.

Food & Beverage

Structural services for production, logistics, and distribution facilities in the food and beverage sector.

Life Sciences

Structural design and retrofits for R&D laboratories, pharmaceutical manufacturing, and biotech facilities.

Manufacturing & Industrial

Engineering expertise for industrial warehouses and production facilities to enhance efficiency and scalability.

Technology & Workplace

Structural solutions for office spaces and dry labs that support tech-driven businesses.

Corporate work spaces need to be flexible and, regardless of size, demand great performance, efficiency, and sustainability. Degenkolb develops structural design and customized equipment bracing solutions to meet our client’s workspace needs and allowing for tomorrow’s innovations.