Leveraging Structural Engineering Design to Improve Delivery of Building Specialty Systems

When trade partners, system vendors, manufacturers, and installers need engineering services for a diverse range of manufacturing systems we can step in, often when other structural engineers will not.

Your project’s success benefits from leveraging our in-house proprietary tools. We work alongside internal research and development teams to craft unique solutions, such as prefabricated components and systems. Additionally, we provide agency review and construction administration support, implementing prompt and responsive documents or design changes.

Specialty systems work requires a deep understanding of the other systems or components, and the inner workings of the system. Full project teams benefit from our holistic approach to building design and systems design.

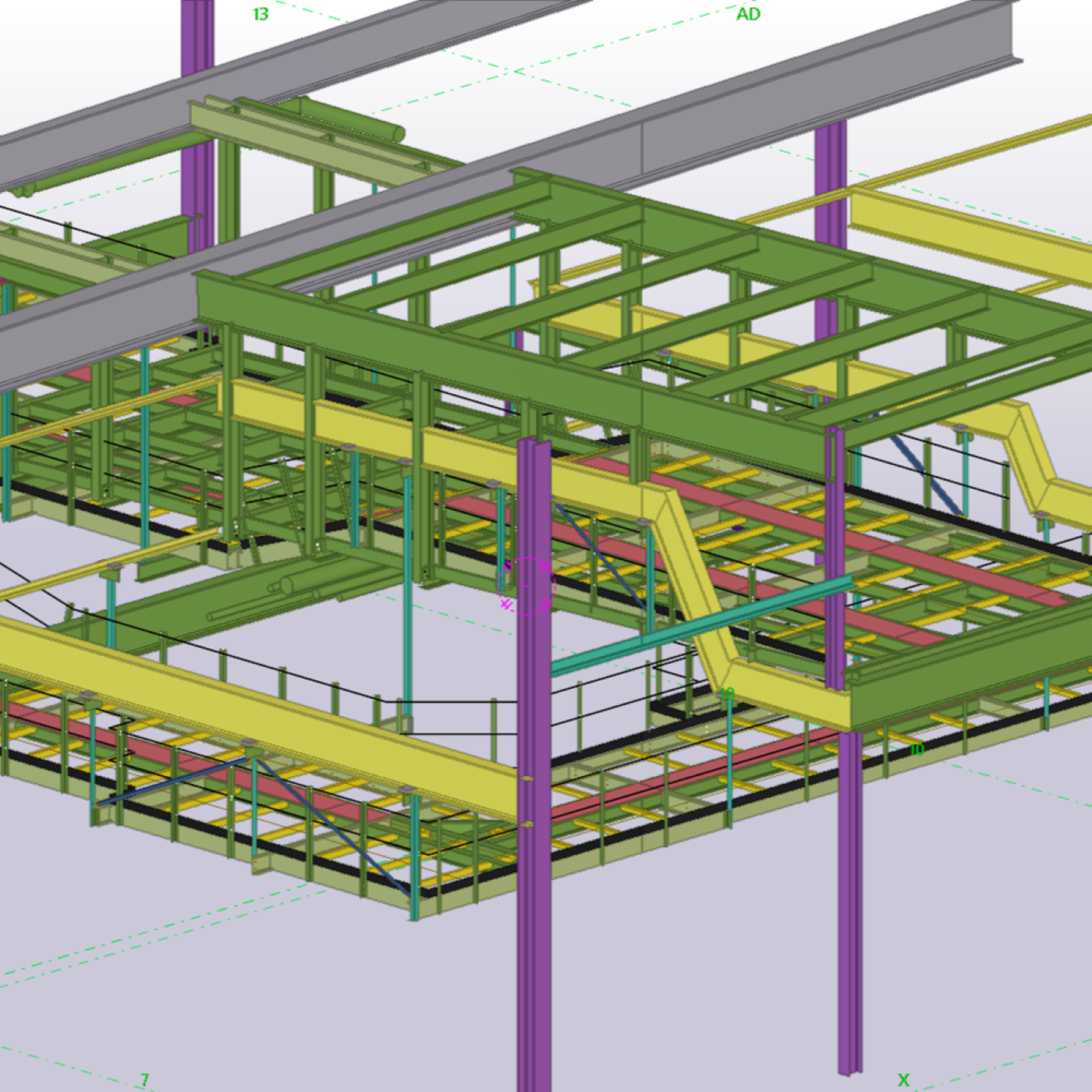

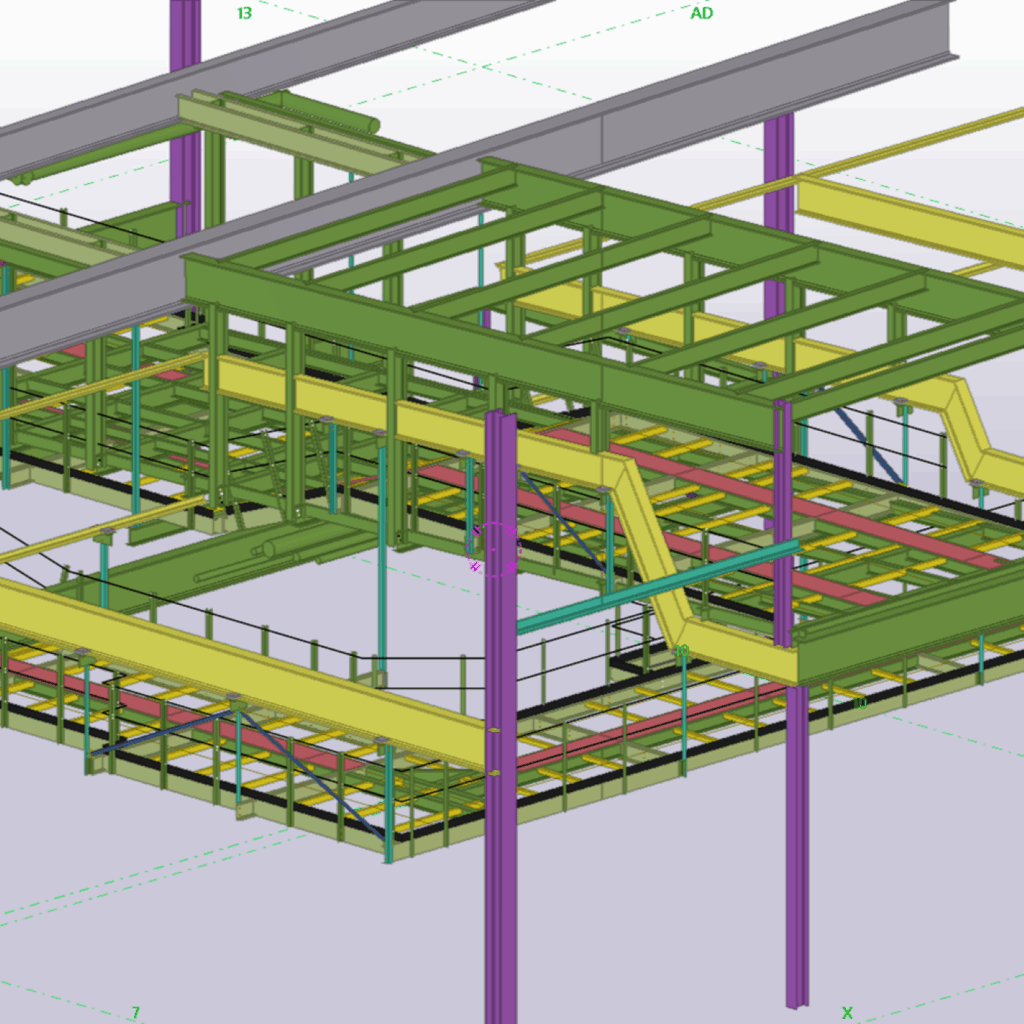

Conveyances

Engineering of vertical and lateral support of baggage handling systems and conveyor systems.

Distribution System Seismic Bracing & Equipment Anchorage

Engineering of vertical and lateral support of piping, ductwork, conduit, and low voltage/technology distribution systems and equipment.

Equipment Anchorage / Preapprovals

Work with equipment manufacturers and installers to develop seismic anchorage details. Frequently, details are submitted to the AHJ (Authority Having Jurisdiction) for preapproval. This work results in additional installation projects in other Practice Areas, implementing the preapproval and/or custom details, and providing construction support.

Metal Stud Framing & Ceilings

Design of metal framing directly for drywall contractors. This group has been expanded to include suspended ceilings. Suspended ceilings is often a scope gap during design of Healthcare projects, since HCAI OSHPD Preapproved Details (OPDs) do not cover all conditions and only include ACT ceilings and metal framed gypsum board ceilings.

Modular Construction

Collaboration with vendors and trade partners to develop modular solutions that minimize costs and maximize efficiency in construction. Current work includes energy/battery skids, equipment platforms, modular Central Utility Plants (CUPs), modular interior wall systems, and OR ceilings.

Special Seismic Certification

Building Codes and owners require some equipment to be shake[1]table tested to ensure that the equipment will function properly after a seismic event. This work is accomplished either on a case-by-case basis or by preapproval. Current projects include consultation on the shake-table methodology and seismicity, working directly with manufacturers or with trade partners planning to install individual equipment.

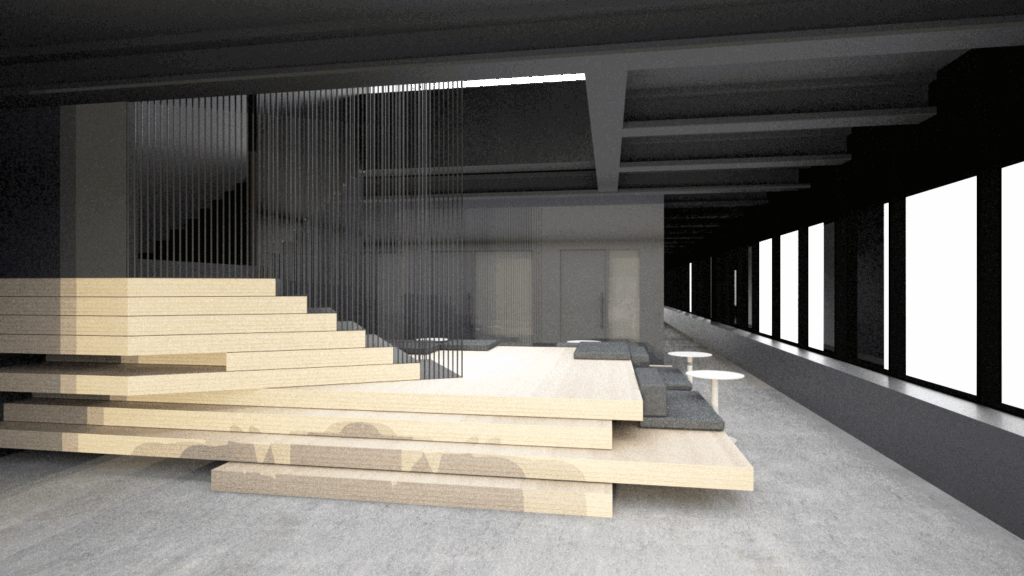

Stairs

Design of feature and egress stairs directly for miscellaneous metals and steel trade partners.

Vertical Transportation:

Work with elevator contractors to design the components and anchorage of the elevator system. Projects range from simple commercial installations to projects under DSA/OSHPD, to modernizations in existing buildings.