Embodied Carbon 101 — Key Takeaways

Degenkolbers recently attended a webinar — Embodied Carbon 101 by The Boston Society of Architects— to educate our engineering staff on structural engineering’s role in carbon emission reduction as part of our involvement with the SE 2050 Commitment. This event kicked off Degenkolb’s broader journey in exploring the relationship between our profession and associated industries with embodied carbon. We compiled some of the key takeaways from the presentation below and invite you to tune into the webinar here and check out other resources by visiting SE2050.org.

Global warming is one of the most significant engineering challenges and societal challenges facing us today.

According to the UN’s Intergovernmental Panel on Climate Change (IPCC), the global average temperature between 1880 and 2012 has risen more than 0.85 C. This has led to calls from the scientific community for immediate action to avoid the most damaging, irreversible effects of the phenomena, “including increases in droughts, floods, and some other types of extreme weather; sea level rise; and biodiversity loss […] causing unprecedented risks to vulnerable persons and populations.” Estimates show we will need to limit the global average temperature change to 1.5 C by the end of the 21st century to avoid these effects.

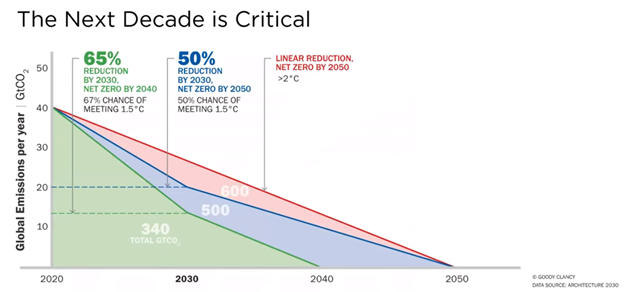

Achieving this lofty goal requires drastic reduction in emissions by 2030 and net zero emissions by 2050; however, this would still only grant a 50% chance of meeting the 1.5C goal.

Additionally, the challenge to reduce emissions will be coupled with a drive to increase global building stock as developing nations join the global stage. Between construction and operation, buildings account for nearly two-thirds of global carbon emissions, with over 50% of them being upfront, which are known as embodied emissions. This presents engineers, architects, and contractors alike with a heavy burden to reduce their carbon footprints, but also an opportunity to lead the charge on combating global warming.

Life-Cycle Assessments (LCA)

During the presentation, one of the main focuses was the utilization of Life-Cycle Assessment (LCA) and its role in carbon reduction. LCA is a process by which a building, component, assembly, or project is analyzed to estimate the environmental impacts over its lifespan. In recent years, many programs have been developed to perform these complex analyses such as Tally, Beacon, and Athena; however, as we gain more information about the products and processes we are using, these analyses become increasingly complex. As a result, a full-scale LCA may not be feasible for all projects. This does not mean that aspects of LCA cannot be incorporated into the design process.

Environmental Product Declarations (EPDs)

Environmental Product Declarations (EPDs) provide critical information about the emissions and environmental impacts of products and can be worked into the design process from the material selection phase without need for performing a whole-building analysis. Additionally, LCA can provide value at the end of a project by performing the analysis and comparing the completed project to others of similar context. Recently, organizations have also started databasing this information to allow for greater exchange of information and project comparison.

In addition to LCA, the webinar offered several strategies that structural engineers could implement in their projects to reduce their embodied carbon footprints.

1. Focus on materials and design processes.

The structure of a building often accounts for greater than 50% of the upfront embodied emissions. By focusing on our materials and design processes, engineers can significantly impact the carbon emissions of our projects.

2. Improve sustainability of materials through reuse and other technologies.

Cement, steel, and aluminum account for approximately 23% of global building sector CO2 emissions, and while not feasible to eliminate them as materials, we can still make great strides to improve their sustainability. This can be achieved by reuse of materials (such as recycled steel and concrete aggregate) and use of carbon-storing materials and technology. While not directly eliminating CO2 emissions, these strategies provide alternative means of offsetting the embodied carbon created by material production.

3. Improve efficiency and end of life design.

Lastly, engineers can further improve sustainability in their structural design by improving material-use efficiency and end of life design.

Addressing global warming is an issue that is paramount to the well-being of our society.

Degenkolb recognizes this reality and is striving to do our part to reduce emissions in our projects. The reality is, however, that our individual action is not enough if it does not encourage others to follow suit. By signing on to SE 2050, Degenkolb is committing not only to reducing our personal footprint, but also encouraging and educating others in our industry how to do so as well.