What You Should Know About Embodied Carbon

We at Degenkolb Engineers signed on to the SE 2050 Commitment Program in the summer of 2021. You can read our official announcement here. The program’s vision: All structural engineers shall understand, reduce, and ultimately eliminate embodied carbon in their projects by 2050. Degenkolb is excited to do our part in eliminating embodied carbon in structures by 2050. To help educate others on structural engineering’s place in the commitment, we have compiled an informational series on the A to Zs of SE 2050, starting first with embodied carbon.

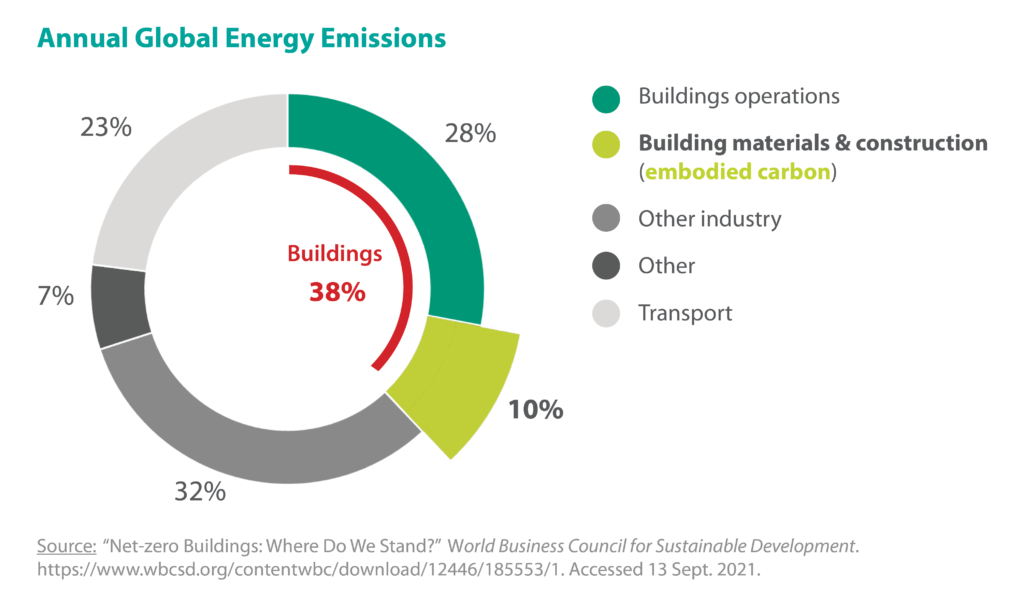

Embodied carbon is the greenhouse gas impact from the construction of a building including mining, manufacturing, and transportation of building materials and the operation of construction equipment. It is the up-front environmental impact of a construction project. The carbon impact from the construction of buildings constitutes 11% of global carbon emissions. Operational carbon describes emissions that occur during the life cycle of a building.

Embodied carbon is measured in CO2-equivalent or CO2-e and is a measurement based on the relative impact of a given gas on global warming or its Global Warming Potential (GWP). Therefore, embodied carbon and GWP are often used interchangeably. For structural materials, embodied carbon is linked to the extraction of the raw material, manufacturing, transportation, construction, maintenance during service life, demolition, and end of life.

Embodied carbon is important for architects, structural engineers, and contractors to address. Building construction and operation contribute significantly to the global carbon emissions, constituting an estimated 38% each year. Of this contribution, 10% of global carbon emissions are estimated to be a result of the building construction industry. This portion is embodied carbon.

As designers and material specifiers, structural engineers have the responsibility and opportunity to meaningfully reduce the environmental impact of the building industry and reduce global carbon emissions.

Structural engineers, through their role in designing the structural system, can have an impact on the embodied carbon of a structure.

Here are five strategies that can be used to reduce a building’s carbon footprint:

- Increase the service life a building. By designing with intention and durability in mind, structural engineers can extend a building’s lifespan and extend the need for replacement. Performing retrofits and renovations extend the service life of the building at a lower monetary and carbon cost than that of a new building.

- Selecting an efficient structural system. Choosing a structural system that meets client needs and optimizes function and material is important in reducing embodied carbon.

- Conduct whole building life cycle assessments to inform decision making. Comparing different systems through their life cycle in a detailed assessment can help choose which will result in the lowest carbon footprint.

- Optimizing materials. In certain applications, using the stronger, more energy intensive materials, such as steel or concrete in lieu of wood, can reduce overall material usage. Identifying when and where each system is appropriate can reduce overall embodied carbon.

- Specify alternative materials such as fly ash or slag in concrete. By using waste by-products from other industries in concrete, these materials are re-purposed and divert from the need to extract more raw materials.

Stay tuned for future additions to the series and, in the meantime, visit SE2050.org for more information.