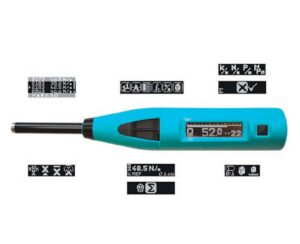

Silver Schmidt rebound hammer Resipod

Degenkolb recently invested in Non-Destructive Testing (NDT) equipment to provide our engineers with information about as-built conditions for their projects.

These new tools operated by Paul Degenkolb will assist the Project Managers and project teams in their facility assessments. The firm, currently testing a handful of tools in the field, intends to grow a resource library for use in evaluation procedures.

The Tools

The Silver Schmidt rebound hammer measures surface level strength of concrete, whereas the Pundit PL200 is an ultrasonic tester intended to determine pulse velocity in concrete up to several feet. The Resipod is a surface resistance meter; the higher the surface resistance, the more the concrete protects the reinforcing steel from corroding. The tools in the Degenkolb NDT library, and accompanied by the Mavic sUAV (Drone), give the engineers and operators the benefit of easier real time access to parts of a structure that are not in safe reach of an unaided person.

The NDT program gauges the apparent condition of a structure to determine if the construction drawings represent the building structure, or if the condition meets normal standards for the type of building. While the NDT program does not provide detailed testing and reporting, it gives Degenkolb’s engineers more insight into field conditions aiding in more rapid evaluations.

Project Uses

Andrew Scott, Principal and Forensics Practice Area Leader approves of the opportunities ahead. “We are excited to deploy these tools on our forensic engineering projects and have already found uses in fire investigation, as-built assessment, and repair of structural deterioration.” With the new and updated tools, Andrew sees an increase in capabilities for future projects.

After implementing the NDT program at Degenkolb, the next step is using the tools on projects. Paul Degenkolb, trained in the uses of each tool, and Jorn Halle, Senior Principal and Healthcare Practice Area Leader, have selected buildings to test the new program. Sampling 30 different buildings into question and inspecting 10 areas in each, the NDT techniques will be used to evaluate general conditions of concrete and to provide Non-Destructive Information (NDI) results on levels, coverage and spacing of reinforced steel throughout the buildings.

Non-Destructive Testing helps assess damage, measure capacities and can improve the decision making process. In-house NDT capabilities gets Degenkolb to the end-point faster, reduces uncertainty and enables project teams to keep moving forward.

Want to know more about Degenkolb’s NDT program and capabilities? Contact Andrew Scott, ascott@degenkolb2024.msidevelopment.com.